Trusted By Over 250,000 Customers!

No Interest, No Payments for 12 months on Select Products

No Interest, No Payments for 12 months on Select Products

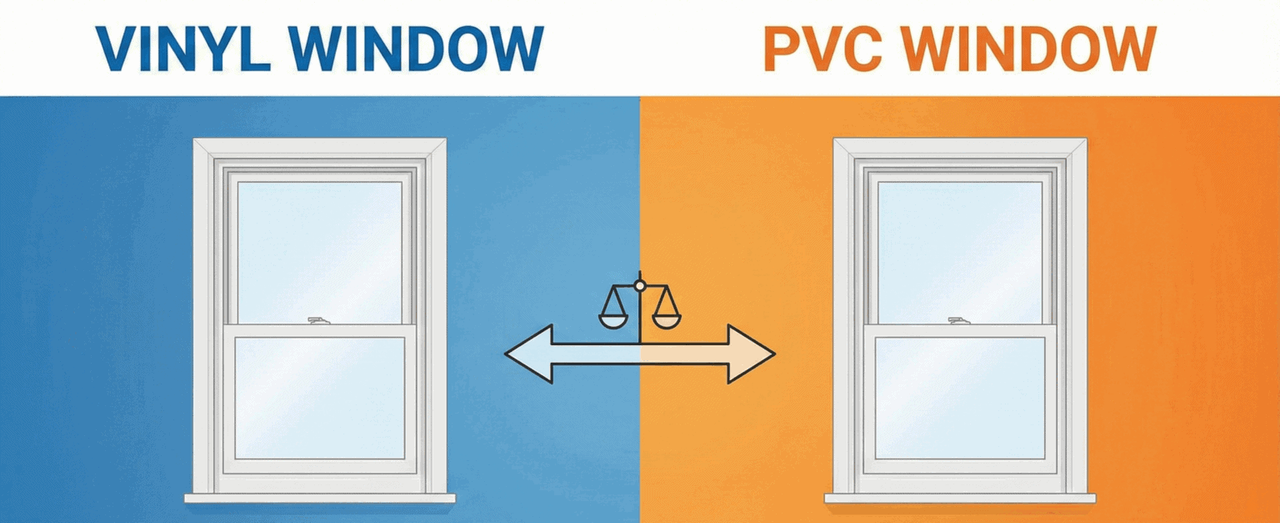

Homes in high-exposure areas require windows that stand up to constant sun, salty air, and the forces of severe weather. Modern vinyl windows are an improvement over aging wood or aluminum, offering polymer frames that resist rot, termites, and UV damage. Because the terms “vinyl” and “PVC” are often used without clear distinction, understanding the difference is essential when selecting replacement windows.

This guide provides a clinical clarification of what each label means, how the two materials technically differ, and why one plastic window material typically offers better long-term value for homeowners.

PVC stands for polyvinyl chloride. In the window market, this term often refers to frames made from rigid, un-plasticized PVC (uPVC). This compound is formed into profiles with internal air chambers that provide insulation and are welded at the corners for a watertight seal. PVC frames generally have limited color options, often restricted to white and light beige, and their reinforcement capacity is modest. PVC is a cost-effective option for homeowners whose primary focus is the lowest possible upfront price.

High-grade vinyl windows begin with the same core polymer but are manufactured with specialized additives and co-extruded exterior layers (capstocks). These refinements allow manufacturers to produce thicker walls, integrate superior weather seals, and offer an expanded color palette, including shades like bronze, clay, and specialized wood-look laminates. While vinyl is chemically a form of PVC, this refined formulation elevates design flexibility and overall performance. A premium vinyl line positions itself as the next functional step up in energy efficiency, durability, and curb appeal.

Window selection should be based on functional experience: achieving lower utility bills, maintaining a strong, reliable seal, and ensuring frames remain stable season after season.

Both PVC and vinyl window frames can be recycled, and their long service life inherently reduces replacement waste. High-performance frames often offset their initial manufacturing carbon footprint in under five years by reducing demand on heating and cooling systems. For improved sustainability, look for vinyl products constructed with recycled cores and capped by high-quality exterior layers, which conserves resources while maintaining colorfastness.

Entry-level PVC windows offer the lowest purchase price. However, upgraded vinyl options frequently recover the price difference through greater insulation performance and fewer service calls over time. These energy savings are substantial and compound over decades, making the more efficient product a sound financial decision.

Building codes in storm-prone regions require windows that can withstand debris strikes and rapid pressure changes. Reinforced vinyl is ideally suited for this due to its internal cavities, which are designed to house steel stiffeners for structural rigidity without creating paths for heat loss. Strengthened vinyl paired with high-performance glass is recommended for certified hurricane windows in storm-prone areas. For guidance on performance criteria, consult our guide on understanding basic window ratings.

Your choice depends on your specific priorities:

For a broad overview of product specifications and design, consult our guide to window types and styles. Regardless of the material selected, the quality of installation is paramount. Professional installers follow precise factory specifications to ensure every component works to its full performance potential. Review our complete line of windows for options in your service area.

Vinyl and PVC windows share a fundamental polymer basis, but modern vinyl uses manufacturing refinements to deliver stronger energy savings, greater design flexibility, and the necessary structure for high-wind reinforcement. While PVC offers a serviceable replacement for aging materials, high-quality vinyl consistently provides greater long-term value in both efficiency and resilience.

As a content manager at Renuity, Francheska spent nearly two years helping homeowners discover the possibilities of transforming their spaces. Renuity is a leader in home remodeling, specializing in everything from windows and doors to bathrooms and home storage solutions, and she’s proud to be part of a team that prioritizes quality, innovation, and customer satisfaction. She graduated from Florida International University with a double major in International Business and Marketing, ranked among the top programs in the nation. Her passion for home improvement runs deep—since childhood, she’s been inspired by watching HGTV and seeing the magic of remodels come to life. Now, she channels that passion into connecting readers with ideas, tips, and solutions to create homes they love.

Renuity is backed by top industry ratings and trusted by homeowners nationwide for quality, service, and reliability.

Offer expires:

plus 12 months, no interest,no or low monthly payments

claim offer

Get a free, no-obligation estimate and see how easy it is to upgrade to your dream home. One of our local specialists will reach out to schedule your consultation—on your terms.

At Renuity, our greatest pride comes from the trust homeowners place in us and the lasting results we deliver. From seamless installations to transformative home upgrades, we’re committed to making every project simple, stress-free, and built to last. Our family of regional brands includes some of the most respected names in remodeling nationwide, all united by proven expertise and a shared commitment to exceptional service. See how we’ve made a difference for families nationwide and what they have to say about their experiences with Renuity.

Outstanding experience from Contact to final sign off. Everyone in this company provided a unique level of customer satisfaction from my experience in this contracting industry. In time calls every ti...

We began our cabinet refacing and pantry installation in October 2025 with Renuity, formerly known as FHIA Remodeling - Jacksonville. Dan, our sales representative, was wonderful to work with. He trul...

The crew: Gregory, Julian, Dani, and Jose, worked well together during this 2-day installation. They each had their own responsibilities and tag teamed the plastic bubble setup, installation, finishi...

The 2 gentleman were very hard workers with proficiency professionalism and very courteous!!! We had 27 windows and front door replaced. The windows were upgraded from 2x2 frames to 2x4 frames with U...

What a pleasant experience we had w/this company! Diego came to fix our window, he respected our time and space. He finished in record time and... cleaned the area and the window. He was amazing. 2 th...

We bought our windows and doors from the company in 2019. It was a great experience, and they always responded quickly whenever we had any concerns. Diego was very helpful, he knew right away what the...

Mike Post was amazing and very thorough. We were well informed about the product, prices, and financing before making our decision. We would definitely recommend them to anyone looking for new windows...

We couldn’t be happier with our shower conversion by Reunity—the craftsmanship, quality, and attention to detail exceeded our expectations. Special thanks to Steven, Jon, and Marty for their professio...

The product is high end, the quality is top notch and the service is impeccable. No grout to maintain! Highly recommend!

We had a wonderful experience with Mike Post our cabinet refacing sells representative. He was very knowledgeable and inviting. He also understood that we were retired and on a budget. His presentatio...